The highest precision of welds preformed thanks to the total control of all parameters involved in the process.

The SUPER Thorn welding machine is a perfect tool for both companies and individuals requiring highest quality and repetitiveness of all welds preformed. The construction of the welding machine is made of special type of grey cast (20 kHz) or aluminium (35 kHz) and the square cross section of the column ensures high resistance to twisting and evening out of the vibrations. It gives the possibility to weld using large pressing power. The adjustable actuator’s height and universal working table based on a ball allow welding of differently sized details using one machine.

Standard frequencies: 20, 30, 35 and 40kHz.

Modern digital control panel SUPER Thorn

Has been invented to deliver highest quality and recurrence of performed welding processes. Both proper programming and clear settings make it fast and reliable. In a case when several different details are used we have an option to define as many as 1024 different memory paths, all of which can be chosen externally. The possibility to set initial downthrust pressure and downthrust while welding allows us to obtain best possible connection. Additionally we are able to control such ad-ons as rotary table , soundproof cabin, adjustable table etc.Available welding options:

- Time: welding using constant time

- Energy: welding using constant energy

- Power: welding using constant power

- Total depth (ABS): welding to a given depth

- Relative depth (DRM): welding to a given depth

The depths is calculated from the moment the detail meets the deliverance power

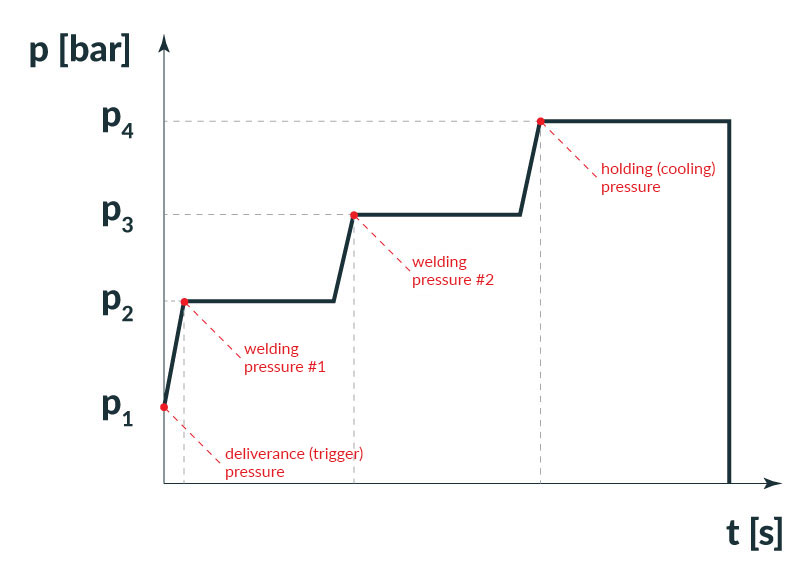

4 types of pressure to allow better control over the quality of welds.

Every Thorn+ DIGITAL series machine has been equipped with pressure control technology using proportional valves. Using that we are able to set, with digital precision, each of the pressures required (every 0,1 bar)

p1 – deliverance pressure

p2 – welding pressure #1

p3 – welding pressure #2

p4 – holding (cooling) pressure

The welding path is controlled with a precision up to 10μm, thanks to the implementation of position encoder.