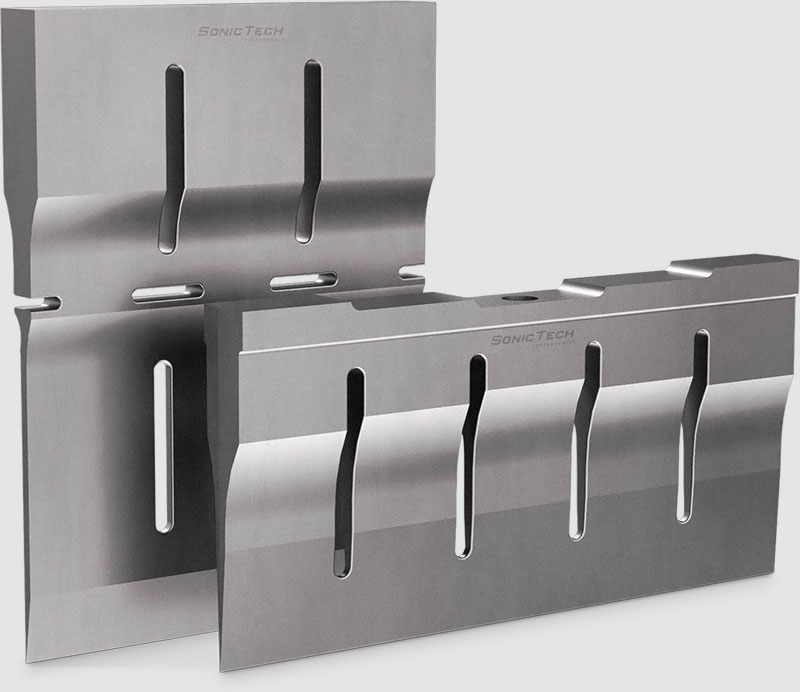

SONICTECH’s titanium sonotrode with proper top surface profile is the highest class component of the welding machine.

Sonotrodes are those parts which are subject to high strains, which is why they must show over ordinary durability. We design and produce them using FEA (Finite Element Analysis)programmes.

We also deliver components to machines of other producers. Each element is carefully tested in our lab and adjusted to a given welding process , what guarantees high robustness and connection reliance for products of many different industries.

Each sonotrode is designed for a specified frequency and vibration amplitude. Typical frequencies used while welding are 20, 30, 35 and 40 kHz. For larger items lower frequencies are used (20 kHz), for smaller items higher frequencies (lower vibration frequency allows making bigger tools)

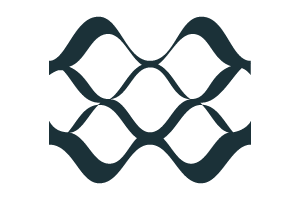

The most important parameter is the vibration amplitude and its equal layout on the top of the sonotrode. If the sonotrode isn’t designed properly, it will not have and even layout of the amplitude, what will result in uneven welding or even can lead to sonotrode’s damage. Having the best possible machine with an incorrectly produced sonotrode will give an average or even incorrect welding results.

SONICTECH Ultrasonics’ sonotrodes with the best welding parameters guarantee

- High speed of the processes

- Repetitiveness of welding results

- Short time span of welding (friction of a second)

- Adjustable to production demand

It is slightly different when it comes to semi-crystalline materials (eg. PP, PA, PE, POM), the melting temperature of which is higher and they are less prone to vibrations. They are also weldable , however it requires much higher vibration amplitude and higher power of the generator.

Below is the simulation of property designed sonotrode.